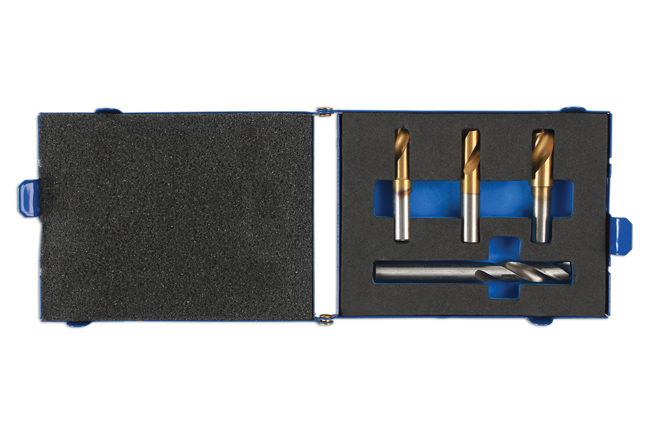

7050 Spot Weld Drill Set 4pc

Designed to cut out spot welds using air powered or electric drills.

- Sizes: 6.5 x 45mm long, 8 x 45mm long, 8 x 79mm long and 10 x 45mm.

- High speed steel Cobalt twist drills with titanium nitride coating.

- Supplied in metal case with foam for safe storage.

- Spare parts available, please see Laser Part No. 60361 (6.5mm), 60362 (8 x 45mm), 60363 (10mm) and 60364 (8 x 79mm).

TSP: £27.12 ex VAT £32.54 inc VAT

Designed to cut out spot welds using air powered or electric drills.

- Der Werkzeugsatz umfasst: 3x 45 mm lange Bohrer: 6,5 mm, 8 mm, 10 mm

- Zusätzlich 1x 79 mm lang x 8 mm

- HSS/Kobalt mit Titanbeschichtung

- Verpackt in Metallkoffer

- Verbrauchsmaterial und nicht von der Laser-Garantie abgedeckt – Ersatzteile verfügbar

TSP: £27.12 ex VAT £32.54 inc VAT

Conçu pour le perçage des soudures par points

- Le lot comprend : 3 forets de 45 mm de longueur : 6,5 mm, 8 mm, 10 mm

- Plus 1 foret de 8 mm de 79 mm de longueur

- HSS/Cobalt avec revêtement en titane

- Livré dans un boîtier en métal

- Consommable et non couvert par la garantie Laser – Pièces de rechange disponibles : 6,5 mm – Référence 60361, 8 mm x 45 mm – Référence 60362, 10 mm – Référence 60363, 8 mm x 89 mm – Référence 60364

TSP: £27.12 ex VAT £32.54 inc VAT

Ontworpen voor het uitsnijden van puntlassen met behulp van pneumatische of elektrische boren.

- Maten: 6,5 x 45 mm lang, 8 x 45 mm lang, 8 x 79 mm lang, 10 x 45 mm.

- Stalen cobalt-spiraalboren met hoog toerental en titanium coating.

- Geleverd in metalen koffer met schuimrubber voor veilig opbergen.

- Reserveonderdelen beschikbaar, zie Laser onderdeelnr. 60361 (6,5 mm), 60362 (8 x 45 mm), 60363 (10 mm), 60364 (8 x 79 mm).

TSP: £27.12 ex VAT £32.54 inc VAT

Useful Downloads

Related Products

Press Release

Easy spot-weld removal with these cutters and drills

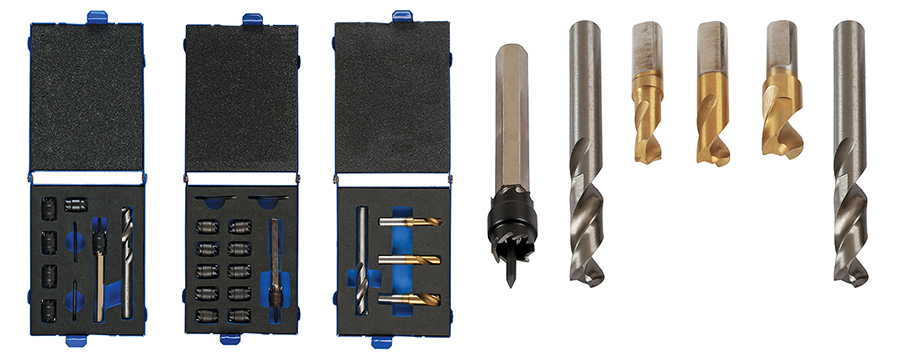

Spot welds: when replacing a spot-welded panel, whether repairing accident damage on a modern car or fitting new bodywork to a classic car, the spot-weld has to be removed cleanly and quickly, leaving the panel underneath undisturbed. Because of the spot-welding process, the metal around the spot-weld has become hardened, so it can be difficult to drill with an ordinary drill bit, plus this will damage the panel underneath. These three new sets from Laser Tools offer two different types of spot-weld remover and offer a complete solution for a variety of panel materials and spot-weld sizes.

The spot-weld cutter set (part number 7048) includes both types of spot-weld remover, the arbour-based spot-weld cutter, with spring-loaded guide pin, and an 8mm spot-weld drill, both designed for use with either electric or air-powered drills. The spot-weld cutter uses double-ended 9.5mm cutter heads which are quickly interchangeable. Six cutter heads are included. A shallow pilot hole is drilled in the centre of the spot-weld; the spring-loaded guide pin then sits in this pilot hole and the cutter then very quickly and accurately removes material around the spot-weld. Stop cutting when the top panel “pops” away from the panel underneath. The special 8mm spot-weld drill is manufactured from HSS cobalt (5%) steel for long life and is suitable for more specialist materials including galvanized high stress steels and alloys where excess heat may be generated. The drill features a special ground self-centring point and “mills” through spot welds to produce burr-free holes, the flat profile protecting the panel underneath.

The spot-weld cutter set (part number 7049) features the arbour-based spot-weld cutter and contains ten spare cutter heads. The spot-weld drill set (part number 7050) features four titanium-coated HSS cobalt (5%) steel spot-weld drills: 6.5mm x 45 long, 8mm x 45mm long, 10mm x 45mm long and 8mm x 79mm.

All three sets are supplied in sturdy, metal storage cases, and are available now from your Laser Tools stockist.